Our key advantages

PhosAgro operates mining and processing assets and boasts its own logistics infrastructure, including two port terminals, along with Russia’s biggest distribution network for mineral fertilizers and feed phosphates. It runs Russia’s only Scientific Research Institute for Fertilizers and Insectofungicides (NIUIF).

Our global operations

PhosAgro is the largest supplier of DAP/MAP and NPK fertilizers in Russia, with a developed domestic sales network and trading offices in all key export markets. It enjoys a strong market position in the premium European market and relies on a netback-driven sales model with a global presence.

Management companies

PhosAgro (Moscow)

PhosAgro-Region (Moscow)

Mining, phosphate rock processing and production operations

Apatit (Cherepovets) and its branches in:

- Balakovo

- Volkhov

- Kirovsk

R&D

NIUIF (Cherepovets)

Distribution

PhosAgro-Belgorod (Belgorod)

PhosAgro-Don (Rostov-on-Don)

PhosAgro-Kuban (Krasnodar)

PhosAgro-Kursk (Kursk)

PhosAgro-Lipetsk (Lipetsk)

PhosAgro-Orel (Orel)

PhosAgro-Stavropol (Stavropol)

PhosAgro-Volga (Nizhny Novgorod)

PhosAgro-SeveroZapad (Cherepovets)

PhosAgro-Tambov (Tambov)

Trading House PhosAgro (Cherepovets)

Phosint Trading Limited (Cyprus)

Phosint Limited (Cyprus)

Phosagro Asia Pte Ltd (Singapore)

PhosAgro Trading SA (Switzerland)

PhosAgro Logistics SA (Switzerland)

Phosagro Polska Sp.z o.o. (Poland)

Phosagro Deutschland GmbH (Germany)

Phosagro France SAS (France)

PhosAgro Balkans DOO (Serbia)

UAB PhosAgro Baltic (Lithuania)

Unique resource base

- A unique resource base with a mine life of around 60 years

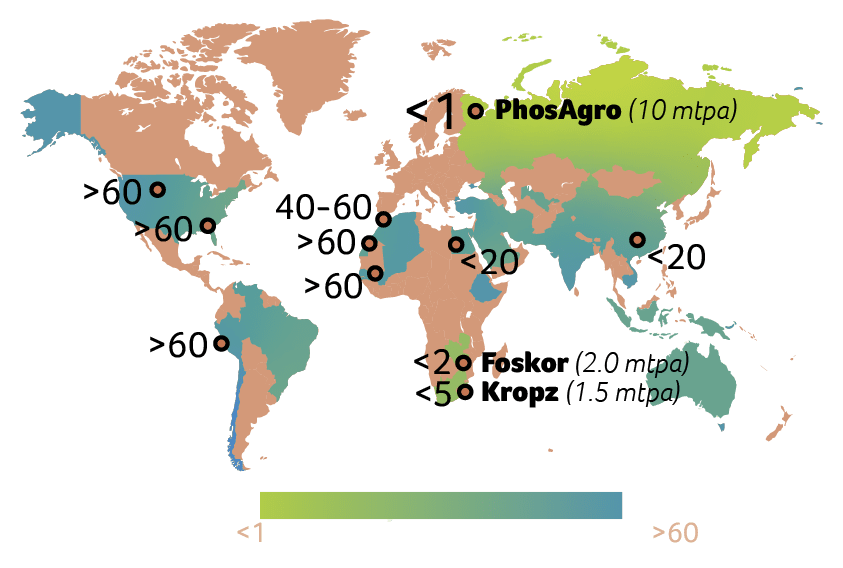

- Lowest content of cadmium (below 1 mg / kg P2O5) and other heavy metals as compared to apatite deposits elsewhere

The initial limitations on the supply of fertilizers with a cadmium content above 60 mg/kg (adopted by the EU Regulation on 21 May 2019, effective from 2022) are estimated to impact 12–15% of the European imports, with further limitations to 40 mg/kg (possible in 2029) affecting as much as 20–30%.

- High-grade phosphate rock with a P2O5 content of 39% or higher

-

Self-sufficiency in major inputs:

100% in phosphate rock,

90% in ammonia

and 90% in sulphuric acid

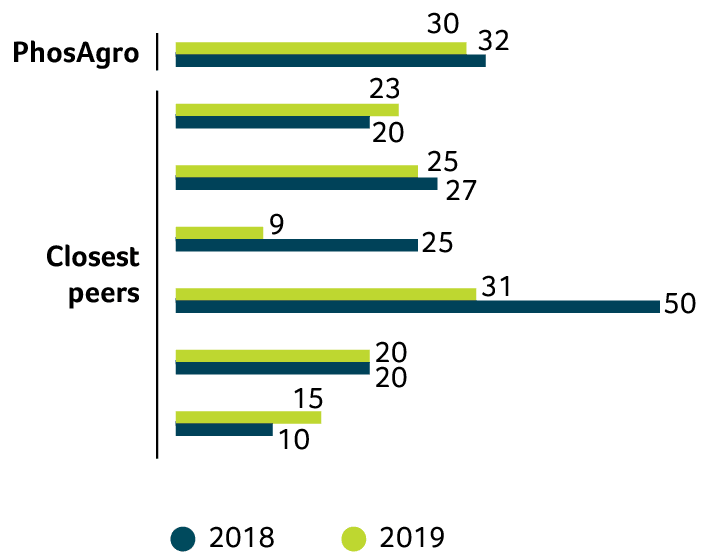

- One of the highest gross margins in the phosphate segment

HIGH QUALITY STANDARDS

- The Group’s production facilities have ISO 9001:2015, ISO 14001:2015, OHSAS 18001, and GMP+ certifications that attest to the high quality of our products and management efficiency throughout their life cycle.

- Products exported to EU customers have been registered pursuant to Regulation (EC) No. 1907/2006 concerning the Registration, Evaluation and Authorisation of Chemicals (REACH).

- PhosAgro successfully passed a certification audit for compliance with the IFA (International Fertilizer Association) Protect and Sustain standard conducted by SGS, the world’s leading inspection, verification, testing and certification company.

- The Company’s processing facilities meet the standards of the best available techniques.

A new ammonia facility with a capacity of 760 ktpa and a granulated urea production unit of 500 ktpa were launched in 2018. The new facilities meet the best available techniques criteria laid out in the Russian Reference Document ITS 2-2015 “Production of Ammonia, Mineral Fertilizers and Inorganic Acids”. Ammonia is produced using an air-cooled process media technology, which minimises water consumption, significantly reducing discharges from the circulation cooling system. State-of-the-art technology of air pre-heating before primary reforming means lower natural gas consumption and air emissions, including greenhouse gases.

The new technology for granulated urea production involves the processing of carbon dioxide associated with the conversion of natural gas as part of ammonia production. This makes natural gas a complex feedstock, with hydrogen and carbon used in ammonia and urea production, respectively. Deeper processing of mineral feedstock results in lower carbon dioxide emissions.

Smart fertilizers

The Company works to make sustainable agriculture a reality by enhancing fertilizer production methods, improving properties and developing new grades of fertilizers, as well as taking part in a number of international initiatives:

- Moving from single products to integrated mineral plant nutrition solutions, which combine several types of fertilizers, including bioadditives, in certain dosages that meet specific soil and climate conditions and crop yield targets. The nutrition systems are tested at numerous field trial stations featuring different soil and climate conditions in cooperation with the leading agricultural education and research institutions.

- Samoilov Scientific Research Institute for Fertilizers and Insectofungicides is part of PhosAgro Group. It develops new fertilizer production technologies and formulas with prolonged effect, as well as slow- and controlled-release fertilizers that can release nutrients at particular phases in line with plant demand.

- Opening the Innovation Centre in 2019 to identify promising development areas and attract external partners such as educational and research organisations, accelerators and innovation parks. The Centre focuses on the projects to produce special purpose fertilizers, biostimulants and growth improving additives.

- Developing the Soil Doctor Testing Kit to be distributed in the countries participating in the programme (5,000 farmers).

- Supporting the Global Soil Laboratories Networks (GLOSOLAN) by developing research capacities and strengthening the Regional Soil Laboratories Networks (RESOLAN). Introducing quality and safety controls across key regional soil laboratories with a focus on fertilizer quality and safety.

Well-balanced corporate governance

- Transparent ownership structure with

over 30% of shares in free float. - Seven (70%) independent non-executive directors on the Board of Directors.

- Six Board committees meeting on a regular basis with five of them chaired by independent directors.

- In 2019, PhosAgro’s Board of Directors established a Sustainable Development Committee at the initiative of Andrey Guryev, CEO, unanimously approving Irina Bokova, an independent director, as the head of the committee. As the Director-General of UNESCO (2009–2017), she participated in the development of the UN Agenda for Sustainable Development, so her highest level of expertise will be a valuable asset helping PhosAgro meet its strategic goals.